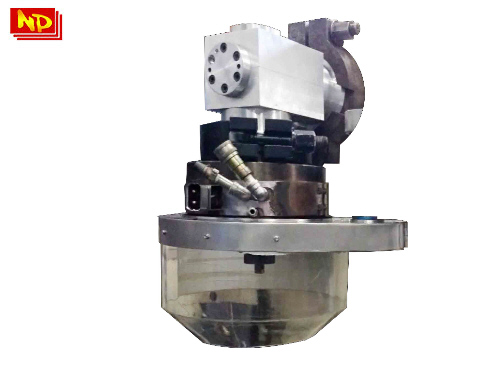

Downward Die Head Attachment

Downward Die Head is an auxiliary device that can be used interchangeably with the direct die head device of the extruder, innovated to achieve better shaped extruded pellets, with the help of natural gravitational pull, the length of extruded pellets can be adjust for more than its standard of 35mm size, its assembly is needed for longer and straighter pellets minimizing bends compared to standard default setup. It has an external driven gear installed to make a stable and consistent form, with the perforated cover and acrylic chute for easy viewing during production. Features: Dimension: Variable cutting speed for ajdusting extruded pellet lenght. Stainless food grade blade holder Specification: Utilities:

|

|